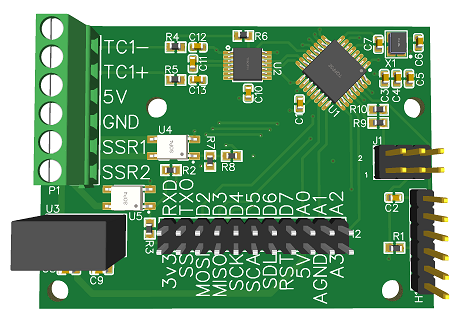

An open source heating and cooling controller for converting a small, desktop mini-oven to a PCB reflow oven.

¶ Specifications

The controller is a single, 60mm x 44mm, PCB design incorporating:

- Arduino based ATMEGA328P processor

- Isolated power supply

- High-accuracy thermocouple interface IC with noise rejection

- 2 SSR channels

- Exposed SPI & I2C interfaces

- General-purpose IO

¶ PCB Assembly

Most of the components on the PCB are SMD, 0603 size. While these are very small, they are still manageable for DIY assembly. There are hundreds of videos online showing various techniques. Alternatively, boards can be ordered populated with surface mount components provided the BOM and pick and place files are correct. JLC PCB offer this service at very reasonable prices and ship to most countries.

¶ Mode of Operation

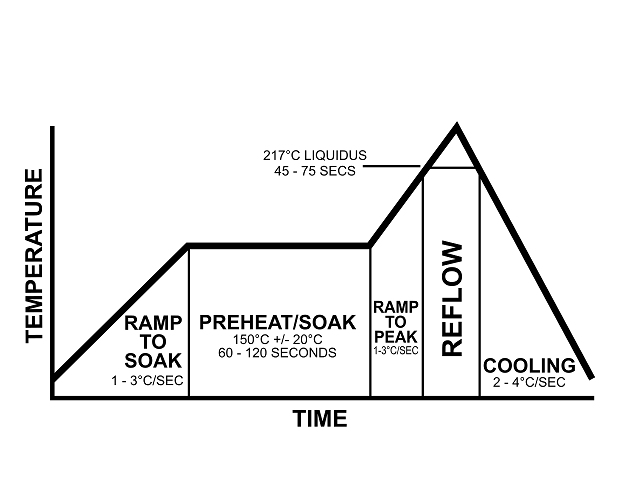

Below is an example of a typical SMD reflow profile1.

For the oven I used in testing, the ramp rate happened to be around the 2°C/second mark, therefore there is no controlled ramp in the firmware. Instead, the profile comprises two segments, a preheat soak and a reflow soak. Both these segments can be adjusted in setpoint value and duration.

The heater output is controlled via means of a PID loop.

¶ Tuning

The controller requires manual tuning of the PID gains to suit the thermal characteristics of the oven used. Detailed understanding of PID control is beyond the scope of these pages but the basic operation can be described as follows.

PID control takes into consideration the proportional instantaneous error (denoted, P, for Proportional), the past error which is integrated over time (denoted, I, for Integral) and an estimated trend of the future error (denoted, D for Derivative).

Below is an animation of the tuning process of a PID loop2.

A simplified view of the tuning process is as follows:

- Increase proportional gain until some overshoot occurs

- Increase integral gain until oscillation at consistent amplitudes occur

- Increase derivative gain until oscillations and overshoot are reduced

Tuning the PID control should be carried out against the reflow setpoint since this is most critical. Usually, the developed terms will work well enough for the preheat temperature also.

Response time and update interval should also be considered. The library allows for setting the update interval. Also within the library is the ability to set bang-bang control. This helps avoid scenarios like integral overwind and controls the system in a thermostatic manor until the process variable is within a defined range of the setpoint where PID control takes over.

The output of the PID control loop is the duty cycle over a 1 second period for the heater. A zero-crossing SSR should be used for an AC-powered application to suppress switching noise.

1, 2 Images taken from Wikipedia.org.

¶ Licensing & Open Source

The Reflow Oven Controller is open source and has been developed with DIY enthusiasts in mind. It is available for anyone to duplicate or modify according to the GPL 3.0 license.